cottorindia@cottor.com +91 (22) 2826 4201 / 2 / 3 / 4 / 28346161

Cottor Plants (India) Pvt. Ltd.

Certified ISO 9001 : 2015 Company

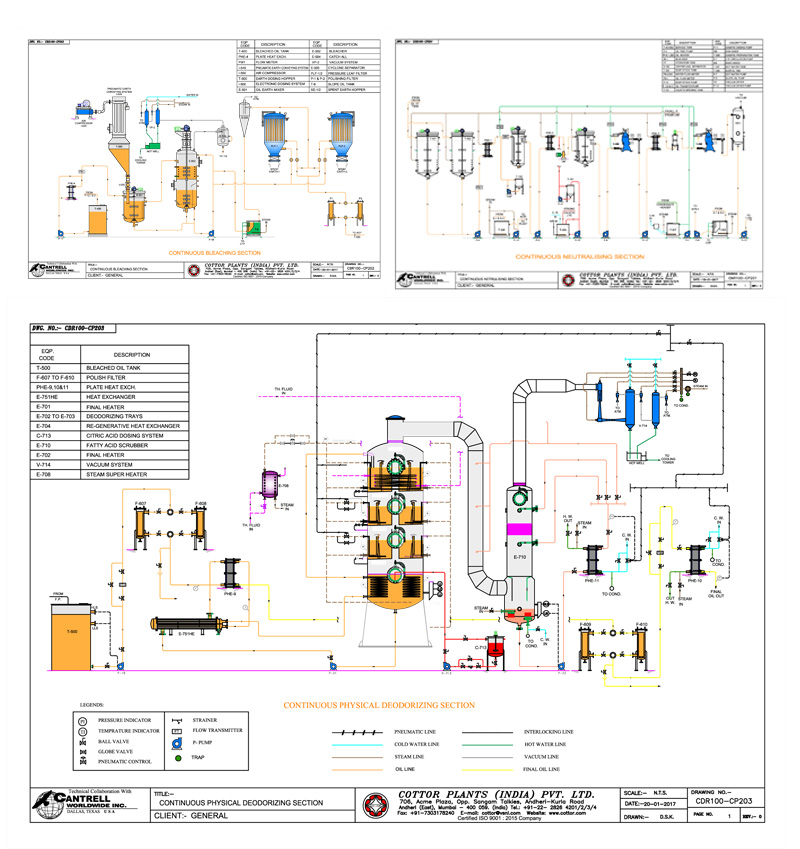

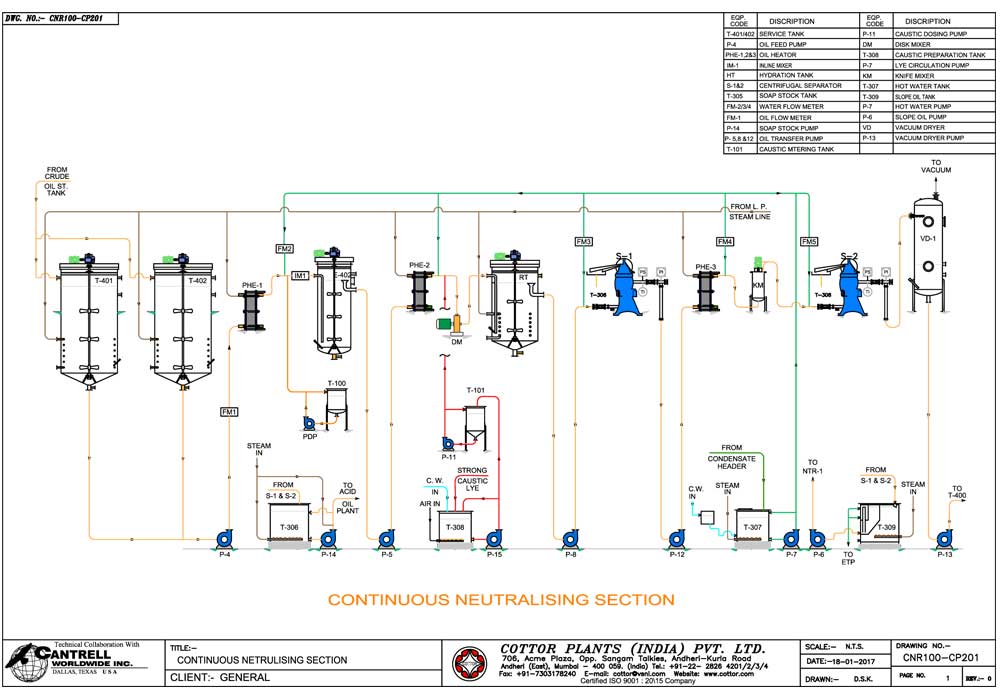

Continuous Refinery Process

Cottor Plants India Pvt Limited has its own success story for Supply, plan and install Continuous Refinery projects in Asia, Africa and even parts of South America. Cottor has been recognised for its quality workmanship and service

initiatives, which is what the industry demands.

Cottor has supplied Vegetable Oil Refinery for most of the Cooking oils right from Soyabean, Sunflower, Cotton Seed, Canola, Rapeseed and Coconut. Cottor has supplied and has full potential to supply projects involving

all aspects of Continuous refinery.

Basic process of refining is same in both batch & continuous refinery. Only difference is, instead of a measured batch, crude oil is processed continuously with constant stream of flow. In between required utilities &

chemicals are added continuously in measured quantity. Basic stages of the process are Neutralizing, Bleaching, Dewaxing & Deodorizing.

Crude oil obtained from expellers / solvent extraction plant contains foreign impurities such as mucilage, gums and unfiltered proteinuous matterfrom the seed.It alsocontains free fatty acid which making it unfit for edible

purpose.

We supply all above sections and all other utilities from Water circulation, Laboratory facilities, ETP, Boiler House, Fire Fighting Equipments, Intermediate Tanks, Bulk Storage tanks and all accessories right from Pipings,

Fittings, Pumps etc. Cottor is known for choosing the best brands and system which ever are outsourced in benefit of customer so as to not affect the project and give highest return of cost per ton / litre of Oil.

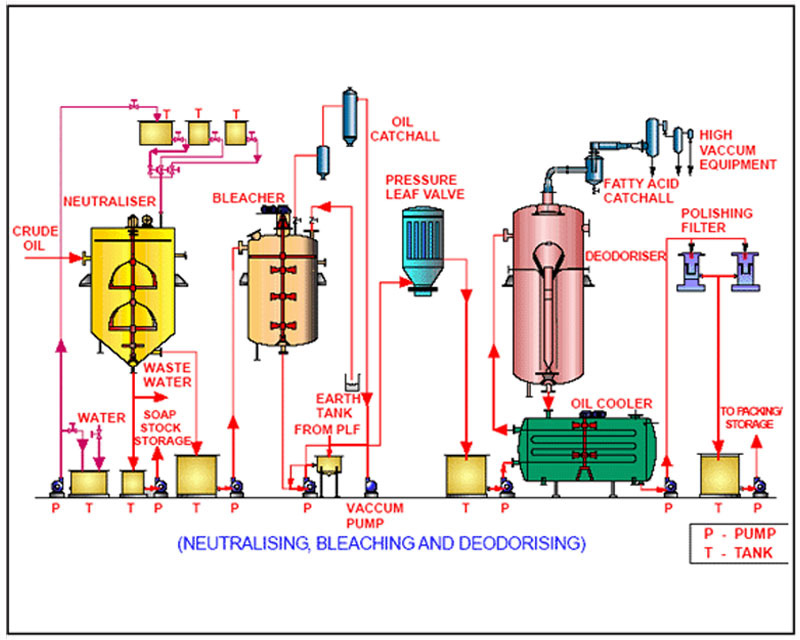

Batch Oil Refinery Process

Cottor Plants India Pvt Limited has supplied and installed many Batch Refinery projects in Asia and African Sub Continent. Cottor has been recognised for its quality workmanship and service initiatives, which is what the industry demands.

Cottor has supplied various capacity of Batch Refinery projects right from 5 tons till 30 Tons Charge for Customers having particular options of refining Vegetable Oil Refinery.

Batch refinery supplied by Cottor has involved most Cooking oils right from Soyabean, Sunflower, Cotton Seed, Canola, Rapeseed and Coconut. Cottor has supplied full projects involving all aspects of Batch refinery right

from Degumming, Neutralising, Dewaxing / Fractionation, Bleaching, Deodorizing, Deacidification and all other utilities from Water circulation, Laboratory facilities, ETP, Boiler House, Fire Fighting Equipments, Intermediate Tanks,

Bulk Storage tanks and all accessories right from Pipings, Fittings, Pumps etc.

Cottor is known for choosing the best brands and system for all outsourced in benefit of customer for a profitable project and give highest return of cost per ton / litre of Oil.

Batch Oil Refinery

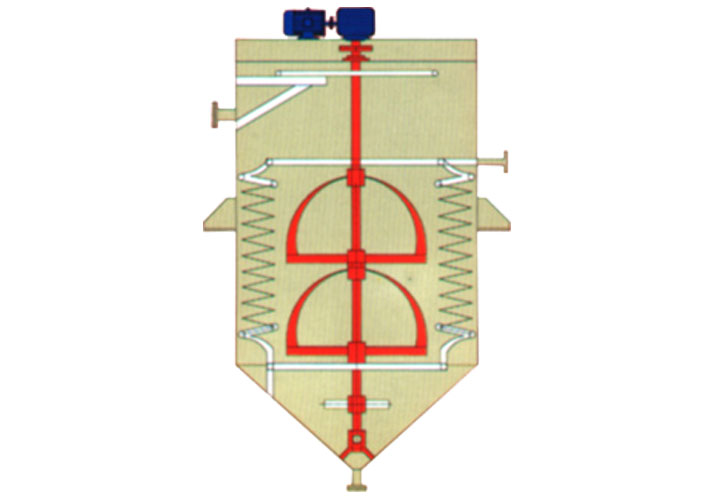

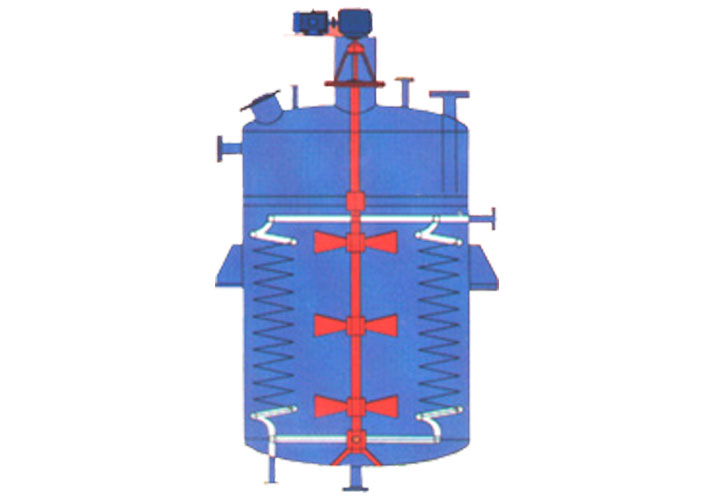

Neutralising Process

- The crude oil is pumped to Neutraliser from oil mill or storage tank & first it is treated with weak solution of phosphoric acid or other suitable degumming agent for removing gums.

- Thereafter oil is further treated with measured quantity of alkali (NaoH) depending upon free fatty acid (F.F.A.) in crude oil. In this process soap will be separated.

- Next process is hot water wash to the oil to remove traces of soap particle & free alkali.

- The oil obtained will be light in colour, free from soap stock & called as washed Neutralised Oil.

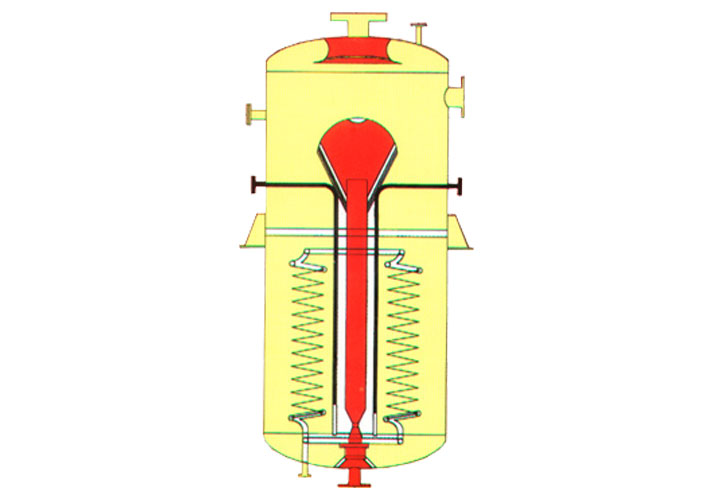

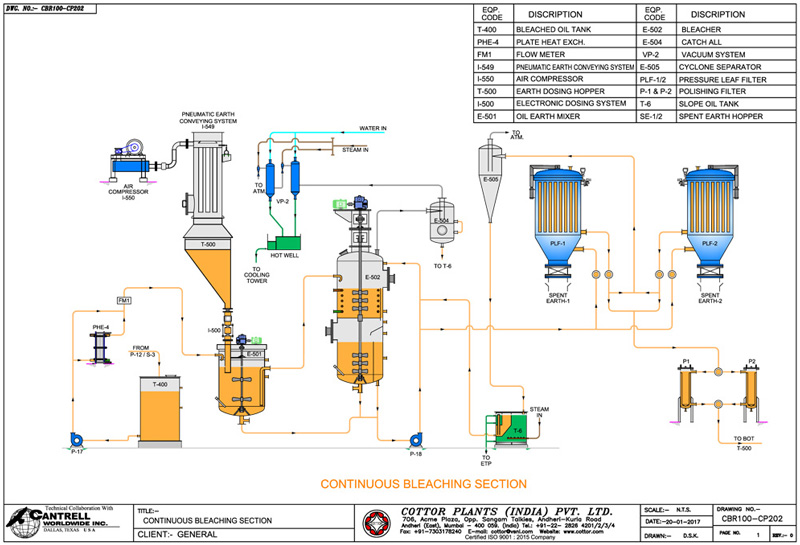

Bleaching Process

- In this process excess colour from the oil is removed. The neutralized washed oil is pumped into the Bleacher vessel operating under vacuum.

- The oil is first heated to remove excess moisture and thereafter it will be treated with predetermined quantity of bleaching earth & activated carbon.

- Thereafter the oil will pass through a filter media (Pressure leaf / Filter press) to separate spent bleach earth and bleached oil.

- The oil will pass obtained after bleaching process is light in colour & appearance of oil will be clear golden in colour.

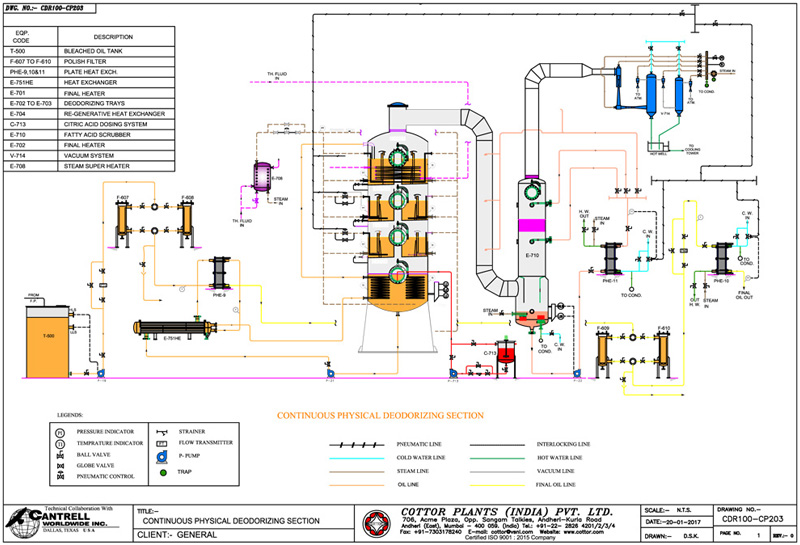

Deodorising Process

- This process removes odour from the oil to improve the quality and self-life of oil.

- The bleached oil is charged to deodorizer directly or through heat exchanger and is heated at high temperature and also under high vacuum in deodorizer vessel to obtain odourless clear oil.

- Once the process cycle is complete the oil obtained will be odourless & light in colour.

- After cooling it will pass through polishing filter to obtained sparkling light colour & odourless oil for packing, which will be used as edible oil.

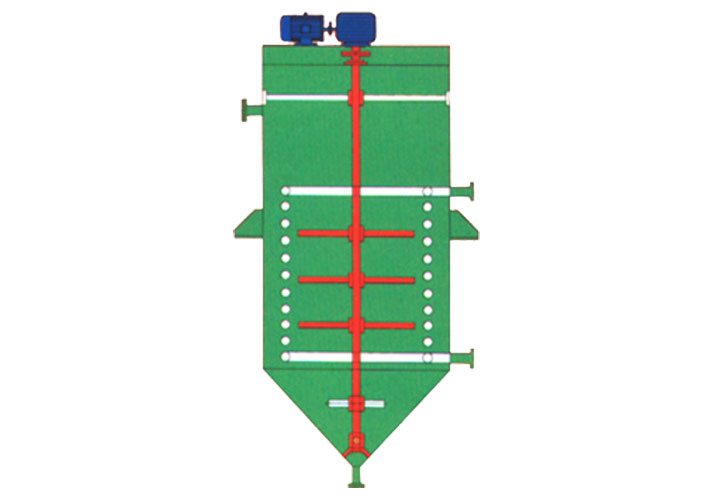

Winterisation (De-waxing Plant)

Sunflower and Rice Bran oil normally contain waxes compared to other oil. Therefore these oils are subjected to de-waxing process called Winterisation Plant, to remove

waxes from oil and to produce sparkling good quality edible oils.

To remove the wax, the oil is first processed in Crystaliser where it is cooled by Chilled water circulation. Where the wax is converted into crystal

form and there after this will be pass through the filteration process.

Now, the wax is separated and the de-waxed oil is collected. This oil will be further processed in the Deodorising section.

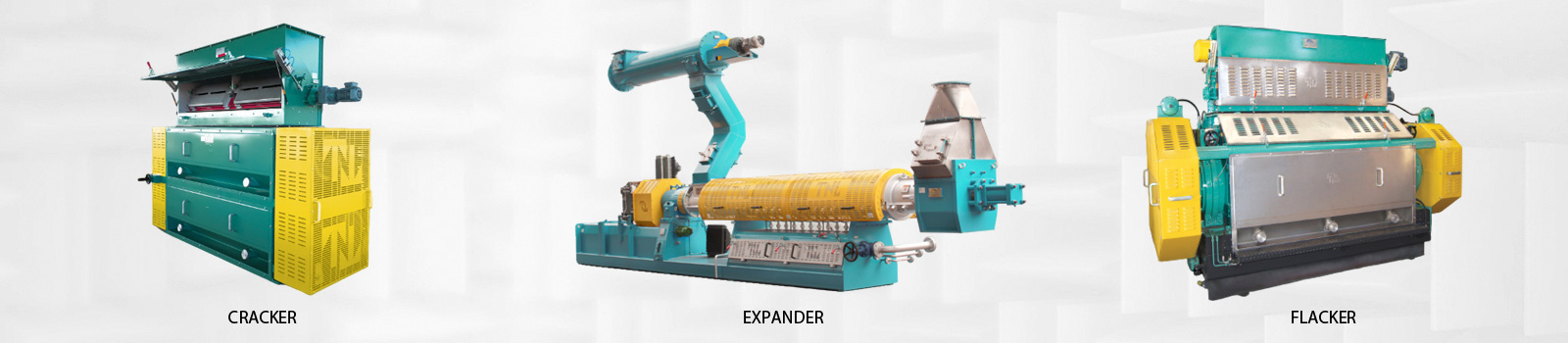

Products

Animated Flow Diagram

Contact Us

Cottor Plants (India) Pvt Ltd,

706, Acme Plaza,

Opposite Sangam Talkies,

Andheri - Kurla Road, Andheri (East),

Mumbai - 400059

Maharashtra, India.

+91 (22) 2826 4201 / 2 / 3 / 4

+91 (22) 2834 6161

cottorindia@cottor.com

All Right Reserved By Cottor Plants (India) Pvt. Ltd.

Designed By Mirackle Solutions